Call Us08045812895

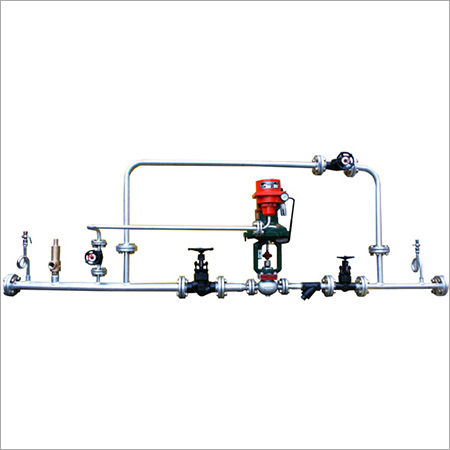

Steam Pressure Reducing Station

150000.00 INR/Piece

Product Details:

- Noise Level <70 dB

- Cooling System Not Required

- Frame Type Modular Skid Mounted

- Lubricating System Not Required

- Drive Steam Driven (no electric drive)

- Accuracy 2% of set pressure

- Operating Temperature Up to 220C

- Click to View more

X

Steam Pressure Reducing Station Price And Quantity

- 1 Piece

- 150000.00 INR/Piece

- Flanged, Screwed, Butt Weld (as per requirement)

- Up to 20 bar(g)

- 15 kg/hr

- Hydro tested up to 1.5 times of design pressure

- Pilot Operated / Spring Loaded

- Up to 12 bar

- Cast Steel / Carbon Steel / Stainless Steel (options available)

- ASME / IBR / DIN

- Included

- Saturated or Superheated Steam Suitable

Steam Pressure Reducing Station Product Specifications

- Modular Skid Mounted

- Steam

- Paint Coated / Powder Coated / Shot Blasted

- Steam distribution, process industries, laundry, hospitals, HVAC, pharma, food & beverage plants

- <70 dB

- Not Required

- Customized per Project

- Steam Process Equipment

- Steam Driven (no electric drive)

- Not Required

- 2% of set pressure

- Up to 220C

- Flanged/Pipe Threaded Connections

- Pressure Reducing Station

- Up to 2500 kg/hr

- Customizable as per Application

- Automatic/Manual

- Mechanical Pressure Reduction

- Industrial Grey / Silver

- Flanged, Screwed, Butt Weld (as per requirement)

- Up to 20 bar(g)

- 15 kg/hr

- Hydro tested up to 1.5 times of design pressure

- Pilot Operated / Spring Loaded

- Up to 12 bar

- Cast Steel / Carbon Steel / Stainless Steel (options available)

- ASME / IBR / DIN

- Included

- Saturated or Superheated Steam Suitable

Steam Pressure Reducing Station Trade Information

- 15 Piece Per Week

- 10-60 Days

Product Description

Our internationally renowned company, is engaged in manufacturing, supplying and exporting Steam Pressure Reducing Station. In our advanced facilities, it is manufactured by dexterous employees using premier-grade metals implementing advanced technology. We offer this product to clients in numerous models to meet the demands of our clients. Offered Steam Pressure Reducing Station is widely used in below listed industries for its excellent operational accuracy, reliable functioning and durability:

- Water treatment plants

- Chemical industries

- Waste water management plants

- Sugar mills

Specification

| Material of Construction | SS |

| Usage | Industrial |

| Size | Customized |

Comprehensive Pressure Control Solution

This steam pressure reducing station features a pilot operated or spring-loaded control valve for precise regulation, ensuring downstream pressure accuracy within 2% of the setpoint. Designed for seamless integration, its automatic or manual operating modes make it suitable for a wide range of industrial steam processes, optimizing both safety and performance in critical applications.

Engineered for Versatility and Reliability

Available in cast steel, carbon steel, or stainless steel, and employing advanced mechanical pressure reduction technology, this station is highly customizable for diverse application needs. The modular, skid-mounted frame and various end connections guarantee simplified installation and compatibility with both new and existing steam lines.

FAQs of Steam Pressure Reducing Station:

Q: How does the steam pressure reducing station regulate steam pressure effectively?

A: The station utilizes a pilot operated or spring-loaded control valve to reduce and maintain downstream steam pressure at a set value, ensuring accuracy within 2% and compensating for fluctuations in inlet pressure or steam demand.Q: What are the benefits of using this pressure reducing station in industrial steam systems?

A: This station improves energy efficiency, protects downstream equipment from overpressure, and ensures consistent steam delivery tailored to various applications such as process industries, HVAC, laundries, hospitals, and food & beverage plants.Q: When should a mechanical steam pressure reducing station be installed?

A: It should be installed whenever precise steam pressure control is essential, especially where varying inlet pressures or multiple usage points are present, to ensure safe and optimal performance of equipment and processes.Q: Where can the steam pressure reducing station be applied?

A: It is ideal for use in a wide range of industries, including chemical processing, pharmaceuticals, food & beverage production, textile plants, hospitals, and commercial heating systems, where controlled steam distribution is crucial.Q: What is the process for installing and commissioning the station?

A: Installation involves integrating the modular skid-mounted unit into the steam line via flanged, screwed, or butt weld connections. After hydro testing and mounting, the station is set to the required downstream pressure and checked for leak-free operation before commencing service.Q: What safety devices are included in the steam pressure reducing station?

A: The station comes equipped with integrated safety devices, such as pressure relief valves and pressure gauges, to safeguard against overpressure and maintain operational safety under varying load conditions.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Steam Pressure Reducing Station' category

|

SAZ BOILERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese