Call Us08045812895

Coal Fired Thermic Fluid Heater

Product Details:

- Air Volume 8000 m/hr

- Thickness 8 mm

- Max Pressure 6 kg/cm

- Temperature 250C

- Max. Capacity 500000 kcal/hr

- Diameter 1100 mm

- Condition New

- Click to View more

X

Coal Fired Thermic Fluid Heater Product Specifications

- Vertical

- 1200 kg

- 5000 L/hr

- 8000 m/hr

- 3400 x 1800 x 2100 mm

- 1100 mm

- New

- 415 V

- 30 HP

- 500000 kcal/hr

- 250C

- 6 kg/cm

- 8 mm

- 5 kg/cm²

- Coal

- Blue/Grey

- Mild Steel

- Shell and Tube

- Thermic Fluid Heating

- Powder Coated

- Manual

- On-site

- Provided

- 78%

- Semi Automatic

- 48

Product Description

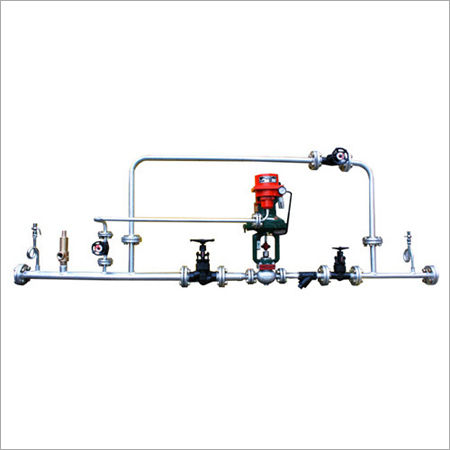

Coal Fired Thermic Fluid Heater is a particularly effective tool for process heating, and they heat high viscosity synthetic oil. In a thermal fluid heater, the process industry can use low pressure to reach the highest process heat temperature. This is typically preferred as using a steam boiler for high temperatures would raise the project's overall cost. Coal Fired Thermic Fluid Heater has a supplementary air system in the furnace for turbulence in a draught of flue gas to maximize heat transfer.

Specification

| Capacity | 1,00,000 to 5,000,000 kcal/Hr |

| Usage/Application | Industrial |

| Automation Grade | Manual |

| I Deal In | New Only |

| Size | Customized |

High-Efficiency Heating for Demanding Operations

With a heater efficiency of 78% and a maximum output capacity of 500,000 kcal/hr, this thermic fluid heater delivers reliable, consistent heating for industrial tasks. Its shell and tube heat exchanger and robust mild steel construction ensure long-lasting performance even in challenging environments, making it suitable for a range of thermic fluid heating applications.

Robust Construction, Safe Operation

Crafted from 8 mm thick mild steel and finished with powder coating, the heater guarantees exceptional durability and corrosion resistance. Safety features like a flue gas outlet, manual ignition, and adherence to working and max pressure standards (5-6 kg/cm2) contribute to its secure, efficient operation.

Customized Installation and Support Across India

On-site installation services are available for seamless integration into your facility. As an exporter, manufacturer, supplier, and service provider based in India, we offer support throughout the product lifecycle, ensuring smooth operation and reliable performance for your business.

FAQ's of Coal Fired Thermic Fluid Heater:

Q: How is the Coal Fired Thermic Fluid Heater installed and commissioned?

A: The heater is designed for on-site installation. Our team of technicians assists with setup, ensuring correct positioning, electrical connections, and integration with the facility's thermic fluid system. Commissioning involves safety checks, initial firing, and calibration of flow rates and pressures.Q: What are the primary benefits of using a coal-fired thermic fluid heater over other heating systems?

A: Coal-fired heaters offer robust and cost-effective heating solutions, especially suitable for regions where coal is readily available. The 78% efficiency ensures optimal energy usage, and the semi-automatic operation provides a balance between manual control and convenience. The robust construction supports long-lasting use in demanding industrial environments.Q: When should the thermic fluid be replaced or maintained in this heater?

A: It's recommended to inspect the thermic fluid regularly and substitute it according to manufacturer guidelines or when signs of degradation (color, viscosity changes) appear. Routine maintenance intervals typically range from 6 months to a year depending on usage intensity and operating conditions.Q: Where can this thermic fluid heater be most effectively used?

A: This heater is ideal for industries requiring consistent thermic fluid heating, such as textiles, chemicals, and food processing. Its design allows for installation in industrial sites across India where space, vertical clearance, and on-site installation are feasible.Q: What is the operational process of the shell and tube heat exchanger in this system?

A: The shell and tube exchanger circulates thermic fluid through multiple pipes while hot combustion gases heat the fluid within the shell. This setup enables efficient heat transfer and supports high flow rates (up to 5,000 L/hr) with stable temperature control (up to 250C).Q: How does the manual ignition system function?

A: The heater employs a manual ignition process. Operators ignite the fuel (coal) in the combustion chamber using appropriate safety practices. After ignition, the semi-automatic controls manage fluid circulation and temperature regulation.Q: What routine checks are necessary to ensure optimal performance of the heater?

A: Routine checks should include inspections of the flue gas outlet, monitoring fluid levels and pressure gauges, verifying surface conditions for corrosion, and ensuring all manual controls function properly. Scheduled servicing as per manufacturer recommendations sustains performance and prolongs equipment lifespan.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Heat Exchangers' category

|

SAZ BOILERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese